Transparent Table Type Epoxy

Table Top Epoxy and Cast Epoxy

As a way to add protection and shine to products, ultra-clear tabletop epoxies are widely used for bars, tabletops, solid tables, jewelry and much more. Epoxy resins are a popular product used for a variety of applications. However, determining the best type of epoxy for your project can be difficult.

Two common types of epoxy are tabletop epoxies and casting epoxies. Whatever epoxy is required for your project, make sure you read and follow the Orhun Kimya tabletop epoxy instructions as mistakes can have a huge impact on the final product.

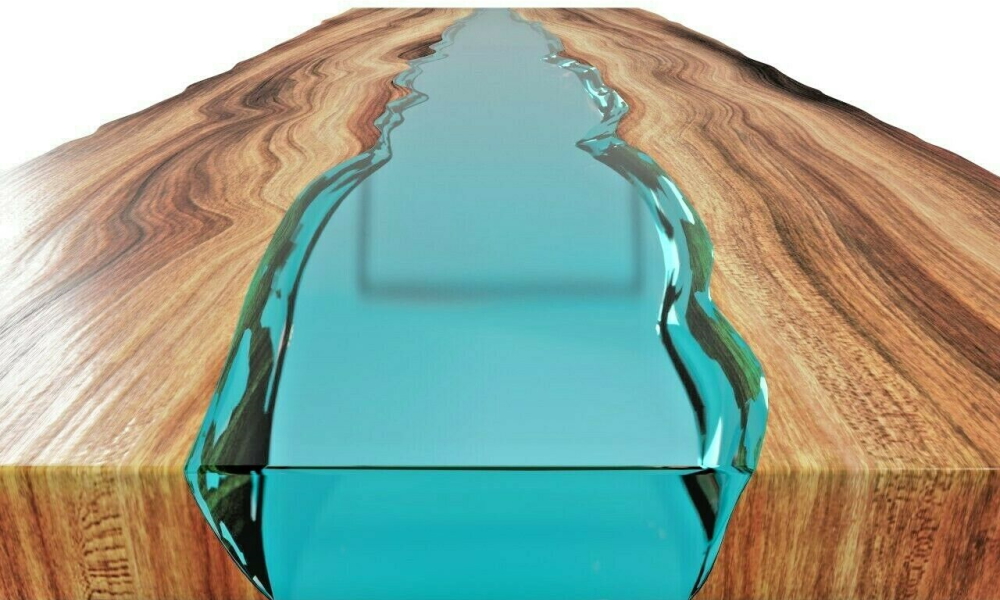

Transparent Table Top Cast Epoxy

The most popular types of ultra clear epoxy are tabletop epoxy and cast epoxy. Tabletop pourable clear epoxy As the name suggests, tabletop epoxy is best for pouring onto flat surfaces such as tabletops, bars, countertops or resin art. It is a self-leveling epoxy designed for thin castings, usually at small thicknesses. Pour thicknesses vary depending on the application, but it’s important to remember that using tabletop epoxy to embed thick objects takes several applications and hours.

With a recommended 1:1 mix of clear tabletop epoxy, it is ideal for beginners and professionals alike. The main advantages of table top pour epoxy are its higher viscosity and faster cure time of 12-24 hours.

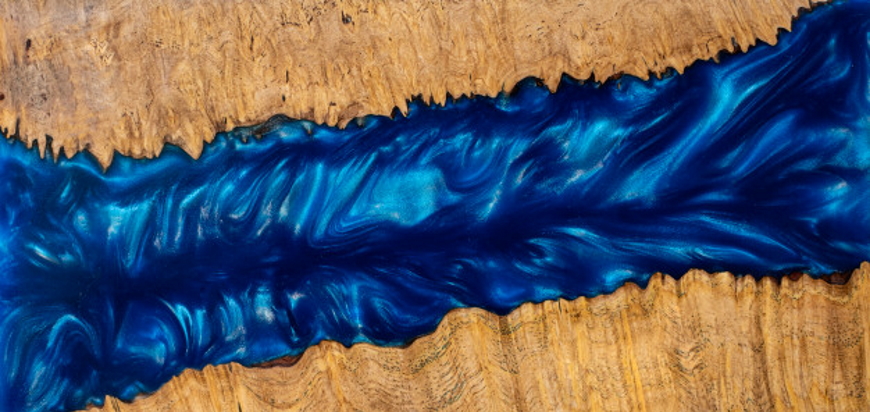

Casting type epoxy, also called deep casting resin, is used for thick castings. Cast type clear table epoxy is commonly used to cover wooden tables. Thick pour clear tabletop epoxy offers lower viscosity and a slower cure rate of 24-36 hours than thin use.

Advantages of Transparent Table Type Epoxies

There are several properties that make clear tabletop epoxies ideal for many applications. The advantages of using clear epoxy in your project include:

- Resistant. Transparent table-type epoxy does not turn yellow or damp even in high humidity conditions.

- High Gloss. For clear tabletop epoxy cures, the formula cures to a highly gloss and clear topcoat. Typically only three coats or more is required to achieve this polished look.

- Simplified Mixing Ratios. Simple mixing ratios make it easy to measure and mix the use of clear tabletop epoxies. This makes it preferred by many as it reduces the risk of minor errors affecting the final product.

- Hard Surfaces. Clear table top pour-on epoxies are formulated to demanding industrial standards and provide the perfect finishes for your project. Epoxy provides long-lasting, maintenance-free surface protection that is resistant to scratches, yellowing and deterioration.

- Adhesion to Wooden Surfaces. Transparent tabletop epoxy is the ideal solution for porous materials, helping to protect the surface while emphasizing the natural properties of wood.

From comprehensive sales and customer service to product development and technical support, Orhun Kimya is here to provide the best solutions for our customers. You can contact us to learn more about our transparent table type epoxy series or to start your epoxy application.